The Next Generation in Semiconductor Decapsulation and Etching

Atmospheric pressure die-level etching of inorganic and organic materials without ion bombardment.

Breakthrough Innovation in IC package decapsulation

Automated atmospheric pressure Microwave-Induced-Plasma (MIP) decapsulation.

What is Microwave Induced Plasma (MIP) decapsulation?

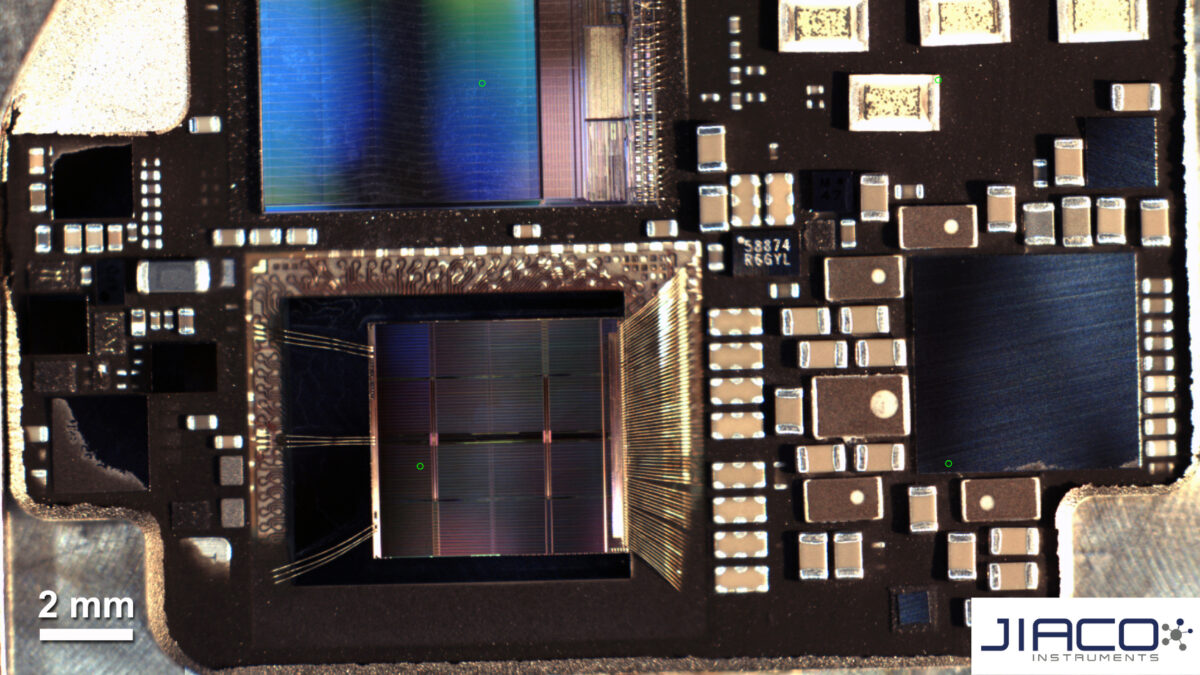

MIP (Microwave Induced Plasma) decapsulation is a technique used to remove the encapsulating material from integrated circuit (IC) packages, allowing for failure analysis and access to the underlying chip and wire bonds. It utilizes atmospheric pressure plasma with oxygen and patented hydrogen-based recipes, offering advantages over conventional plasma etching methods.

MIP decap is a method to remove the encapsulant (e.g., glob-top, underfill) from IC packages without damaging the die, wire bonds, or critical structures.

The IC decaping using MIP allows engineers to examine the chip and its connections for failure analysis, reliability testing, qualification, or cybersecurity.

JIACO Instruments is a company known for developing Microwave Induced Plasma and providing MIP decapsulation systems to failure analysis and reliability labs.

How does MIP work?

Chemical Radicals

MIP decapsulation uses a microwave-induced plasma to create chemical radicals for isotropic etching.

Oxygen and Patented Hydrogen Recipes

This plasma is generated using oxygen and a patented hydrogen-based recipe, ensuring minimal damage to the IC components.

IC Package Decap

It is particularly effective for decapsulating complex IC packages like 3D, SiP, and BOAC devices, among others..

Advantages of MIP Decapsulation

Preserving Critical Structures

MIP decapsulation avoids the overetching damage caused by conventional plasma etching methods, especially when dealing with thin copper metallization traces on passivation.

Rapid Sample Preparation

The process is efficient and allows for quick access to the area of interest during failure analysis.

Minimizes Artifacts

MIP decapsulation helps avoid the introduction of artifacts that could contribute to uncertainty in the fault detection process.

Versatile

It's suitable for various IC packages and wire bond types, including Cu, PCC, Ag, and Au.

Applications for MIP

Failure Analysis

Failure analysis of ICs.

Reliability Testing

Reliability testing of ICs.

Qualification

Qualification procedures for new processes and materials.

Cybersecurity

Recover lost data, test vulnerabilities.

Our Microwave Induced Plasma (MIP) Systems

MIP | IC Decapsulation

Automated atmospheric pressure MIP IC decapsulation utilizing only Oxygen and patented Hydrogen-based recipes. MIP is the global standard for tackling the semiconductor industry’s most demanding decapsulation challenges.

Learn More

Learn More

MIP+ | Die-level Etching

The Next Generation in Semiconductor Decapsulation and Etching. MIP+ extends MIP’s proven capabilities from package-level to die-level etching.

Learn More

Learn More